Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2025-11-12 14:53:28

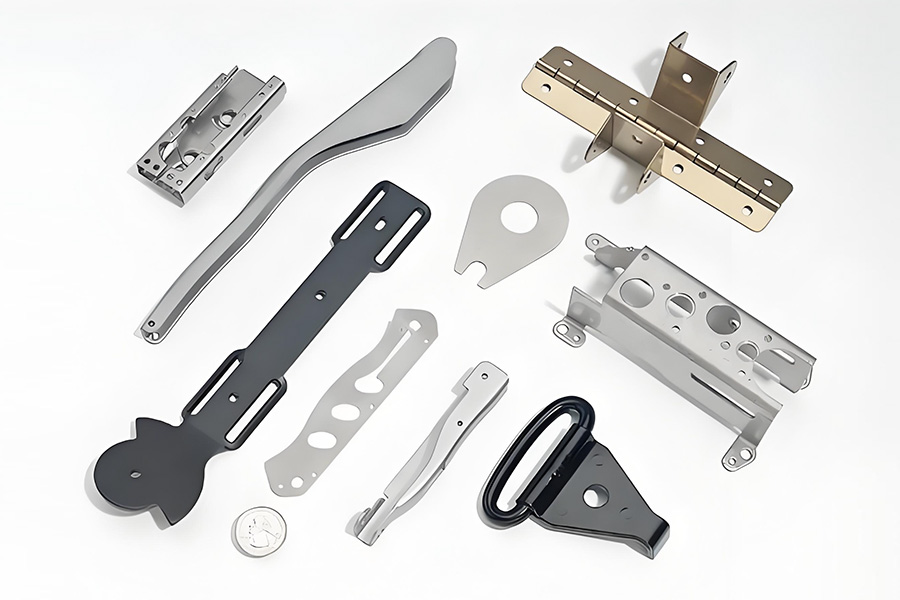

Amid the wave of modern manufacturing transforming towards high precision, intelligence, and green development, precision Sheet Metal Fabrication, as a core link in the machinery manufacturing field, is breaking the limitations of traditional processing models through the in-depth integration of a series of advanced technologies. From cutting, forming, and welding to surface treatment, as well as full-process intelligent control and precision inspection, the application of advanced technologies has not only greatly improved processing accuracy and production efficiency but also expanded the application boundaries of precision sheet metal parts in high-end fields such as aerospace, automotive manufacturing, electronic equipment, and medical devices, driving the high-quality development of the industry.

Cutting is the initial process of precision Sheet Metal Fabrication, and its accuracy directly determines the quality of subsequent processes. Currently, high-energy fiber laser cutting and 3D laser cutting technologies have become the industry mainstream, completely changing the pattern of traditional mechanical cutting.

High-energy fiber laser cutting has become the "benchmark technology" for precision sheet metal cutting due to its outstanding performance. This technology uses a laser beam generated by a high-power fiber laser, which is focused to form an extremely small spot, instantly releasing extremely high energy to rapidly melt and vaporize the metal sheet at high temperatures, thereby achieving non-contact cutting. Compared with traditional plasma cutting and flame cutting, fiber laser cutting has significant advantages: the cutting accuracy can be stably controlled within ±0.05mm, the heat-affected zone width is less than 0.1mm, which can minimize material deformation and ensure the consistency of part dimensions; the cutting surface is smooth and flat, without burrs or slag, eliminating the need for subsequent grinding and greatly shortening the production cycle; at the same time, the laser beam can accurately adapt to the cutting of complex 2D graphics, whether it is fine hollow structures or complex curved contours, it can be completed efficiently. It is especially suitable for the processing of products with strict requirements on precision and appearance, such as electronic equipment casings and medical device components. Currently, with the maturity of high-power fiber laser technology, the cutting speed of a single equipment has been increased to 3-5 times that of traditional cutting equipment, and it can be compatible with various metal materials such as stainless steel, aluminum alloy, copper, and titanium alloy, meeting the processing needs of multiple industries.

3D laser cutting technology has broken through the limitations of planar cutting, providing an efficient solution for the processing of complex 3D structural sheet metal parts. By combining the laser cutting head with a multi-axis robotic arm or a gantry-type motion platform, and cooperating with advanced path planning software, this technology can achieve precise cutting of thick plates, special-shaped parts, and 3D curved sheet metal parts. During processing, the robotic arm can flexibly adjust its posture according to the three-dimensional contour of the sheet metal part, ensuring that the laser beam is always perpendicular to the cutting surface, effectively avoiding the error accumulation caused by traditional multi-process splicing processing. For example, in the aerospace field, the special-shaped frames of aircraft fuselages and the complex structural parts of engine nacelles can be cut and formed in one go through 3D laser cutting technology, which not only reduces mold investment and process conversion time but also increases the part qualification rate from 85% of the traditional process to More than 99%; in automotive manufacturing, the processing of special-shaped components such as door inner panels and bumper brackets also achieves the dual goals of lightweight design and high-precision manufacturing with the help of this technology.

The forming process is a key link in shaping the geometric shape of sheet metal parts. Advanced intelligent forming technology is developing towards high precision, flexibility, and automation, which not only ensures the forming quality of parts but also improves production flexibility.

Automatic flexible bending technology is one of the core innovations in the forming link. Different from traditional single-axis bending machines, flexible bending equipment adopts multi-axis coordinated control, which can perform symmetric bending on both sides or four sides of the sheet metal part at the same time. It reduces the contact area between the mold and the material through the wing-shaped bending principle, reducing mold wear and avoiding indentation defects on the surface of the sheet metal part. The core advantage of this technology lies in "flexible adaptation": combined with professional sheet metal bending software, it can pre-program and simulate complex bending paths, supporting the automatic execution of multi-step bending processes without frequent mold replacement; at the same time, the equipment can seamlessly connect with previous processes such as coil leveling and stamping lines to form a continuous production process, which can not only meet the efficient production of large-batch standardized products but also quickly adapt to the customized needs of small-batch and multi-variety. In the processing of products such as electronic equipment chassis and communication equipment casings, flexible bending technology can control the bending accuracy within ±0.03mm, greatly improving the assembly accuracy and interchangeability of products.

Precision hot stamping technology has achieved a dual breakthrough in material performance and forming accuracy to meet the processing needs of high-strength and lightweight sheet metal parts. The core process of this technology is: first, heat the high-strength steel plate to a specific austenitizing state, quickly transfer it to a special mold for stamping forming, and complete quenching and cooling in the mold at the same time. The sheet metal parts processed by this process have a tensile strength of 1400-1600MPa, which can achieve the lightweight design of the car body while ensuring the strength of the car body. In the field of automotive manufacturing, this technology is widely used in the production of key load-bearing components such as car body anti-collision beams and A/B pillars. It can not only improve the collision resistance of the car body but also help the car achieve lightweight and reduce energy consumption; in the field of construction machinery, the application of high-strength sheet metal parts has also realized the miniaturization and high efficiency of equipment through this technology.

Welding is a key process for realizing the splicing and assembly of sheet metal parts. The application of automated welding technology has effectively solved the pain points of low efficiency and unstable quality of manual welding, providing a guarantee for the reliable connection of precision sheet metal parts.

Robotic welding technology has become the mainstream choice for precision sheet metal welding. Its core lies in controlling the welding path and parameters of the robot through preset programs to achieve automated and high-precision welding. Compared with manual welding, robotic welding has advantages in three aspects: first, strong stability. The robot can always maintain consistent welding speed, current, voltage and other parameters, the weld seam is uniform and flat, and the defect rate is less than 1/10 of manual welding, which is especially suitable for the consistency requirements in mass production; second, high efficiency. The welding speed of the robot can reach 2-3 times that of manual welding, and it can realize 24-hour continuous operation, greatly improving production capacity; third, wide adaptability. Equipped with flexible positioning welding fixtures and positioners, the robot can flexibly adjust the positioning method according to the structural characteristics of different sheet metal parts, reducing fixture costs and adapting to non-standard customized production. In the welding of new energy vehicle battery trays, medical device racks and other products, robotic welding technology not only ensures the tightness and strength of the weld seam but also effectively controls welding deformation, ensuring the assembly accuracy of the product.

Laser tailor-welded blank technology provides an innovative idea for the structural optimization of sheet metal parts. This technology can accurately weld metal sheets of different materials, thicknesses and performances into one body through laser welding, and then perform subsequent forming processing. Its core value lies in "on-demand design": according to the force requirements and protection requirements of different parts of the sheet metal part, select the appropriate material to achieve the optimal configuration of material performance. For example, in automotive body manufacturing, high-strength steel can be used for the load-bearing parts of the body, ordinary low-carbon steel for non-load-bearing parts, or aluminum alloy and steel can be spliced together, which not only ensures the structural strength and safety of the body but also minimizes the weight of the body; in the processing of electronic equipment casings, aluminum with good heat dissipation performance and stainless steel with high strength can be spliced to balance heat dissipation needs and structural stability. In addition, laser tailor-welded blanks can reduce the number of parts, simplify the assembly process, and reduce production costs, which has become a key technology to achieve product lightweight and high performance in high-end manufacturing.

Surface treatment is an important process to improve the corrosion resistance, wear resistance and aesthetics of precision sheet metal parts. Advanced surface treatment technology is developing towards environmental protection, automation and high efficiency, realizing green production while ensuring product performance.

Automatic environmental protection spraying technology has become the mainstream trend in the industry. This technology integrates an automatic pre-treatment line and an automatic spraying line to form a closed-loop production process: in the pre-treatment stage, the sheet metal parts pass through more than 18 heating water tanks to complete degreasing, derusting, phosphating and other processes in turn. The temperature and time of each link are precisely controlled by an intelligent system to ensure that the surface cleanliness of the substrate meets the standards; in the spraying stage, powder electrostatic spraying or water-based coating spraying technology is adopted. Compared with traditional solvent-based coatings, it can reduce VOC (volatile organic compounds) emissions by more than 90%, meeting environmental protection requirements. At the same time, real-time monitoring equipment such as furnace temperature testers and film thickness gauges are equipped during the production process, which can accurately control the coating thickness and curing quality, ensuring that the coating has strong adhesion and good uniformity, and is not easy to fall off or fade. In the processing of products such as home appliance casings and industrial equipment covers, automatic environmental protection spraying technology not only improves the appearance texture and durability of products but also reduces environmental protection treatment costs, realizing the unification of economic and environmental benefits.

Plasma spraying and laser cladding technologies provide surface strengthening and repair Solutions for the special performance requirements of high-end precision sheet metal parts. Plasma spraying technology uses the high temperature of the plasma arc to melt coating materials such as ceramics and cermets, and then sprays them onto the surface of the sheet metal part at high speed to form a high-hardness, high-wear-resistant and corrosion-resistant coating. It can increase the surface hardness of the part by 3-5 times and greatly extend the service life. It is often used for high-frequency stress-bearing and easy-wear sheet metal components in industrial equipment; laser cladding technology melts and solidifies the alloy powder and the surface material of the sheet metal part together through a laser beam to form a metallurgically bonded strengthening layer. It can not only improve the surface performance of the part but also accurately repair worn and defective parts, restoring the original performance of the waste parts and even realizing performance upgrading. It has important application value in the maintenance and manufacturing of high-end equipment such as aerospace and construction machinery.

With the deepening of Industry 4.0 concepts, intelligent control and precision inspection technologies have run through the entire process of precision sheet metal fabrication. From raw material warehousing to finished product delivery, they have realized the transparency and controllability of the production process, providing comprehensive guarantee for product quality.

The construction of an intelligent flexible production system has enabled precision sheet metal fabrication to achieve an "unmanned" and "intelligent" production mode. With the ERP (Enterprise Resource Planning) system as the core, the system links automatic stereoscopic warehouses, intelligent nesting software, processing equipment and data collection terminals to form a complete production closed loop: after raw materials are warehoused, the system automatically records information such as material and specifications, and automatically completes production scheduling and nesting according to order requirements to maximize material utilization; cutting, bending, welding and other equipment cooperate through the industrial Internet, and processing parameters are uploaded to the system in real time. Managers can remotely monitor production progress through intelligent terminals; after finished products are warehoused, the system automatically updates inventory information to achieve precise control of order delivery. For example, a precision sheet metal enterprise has increased material utilization rate from 75% to 88%, shortened production cycle by 30%, and achieved an order delivery punctuality rate of 99% by introducing an intelligent flexible production system, greatly improving the core competitiveness of the enterprise.

Multi-dimensional precision inspection technology has become the "sharp eye" for quality control, covering the full-chain inspection needs from materials to finished products. In the material inspection link, equipment such as Spectrodesk direct-reading spectrometers can quickly detect the elemental composition of metal materials to ensure that the raw materials meet the processing requirements; at the same time, the mechanical properties of the materials are tested through tensile testing machines and hardness testers to provide a basis for the setting of processing parameters. During processing, non-destructive testing technologies such as ultrasonic flaw detection and penetrant testing are used in the welding link to accurately identify internal weld defects such as cracks and air holes, ensuring welding quality; for products with high airtightness requirements, such as medical device casings and automobile fuel tanks, helium mass spectrometers are used for airtightness testing, and the leakage rate can be controlled below 10-9Pa·m³/s. In the finished product inspection link, coordinate measuring machines, laser scanners and other equipment are used to conduct comprehensive inspections on the dimensions and geometric tolerances of parts to ensure that the products meet design standards; for precision sheet metal parts related to semiconductors, electrostatic discharge protection performance testing is also carried out to meet the usage requirements of special industries.

From the precise breakthrough of cutting technology to the flexible upgrade of forming processes, from the stable and efficient welding technology to the green and environmental protection of surface treatment, as well as the full-process intelligent control and precision inspection, advanced technologies are reconstructing the industrial ecology of precision sheet metal fabrication. In the future, with the in-depth integration of artificial intelligence, digital twin and other technologies with processing processes, precision sheet metal fabrication will move towards higher precision, higher efficiency and more intelligence, providing stronger support for the development of high-end manufacturing and continuously creating greater industrial value.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2026 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang