Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2025-11-21 13:50:24

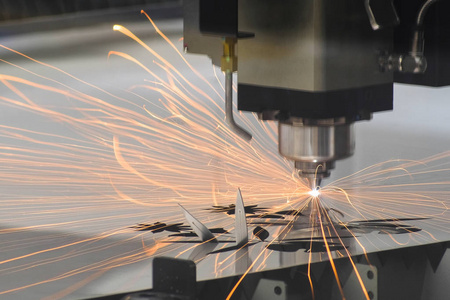

Laser Cutting is a transformative subtractive manufacturing technology that utilizes a high-power, focused laser beam to precisely cut, engrave, or mark materials. This process, governed by the principles of optics and thermal energy, has revolutionized industries ranging from heavy manufacturing to delicate electronics. Its ability to deliver exceptional accuracy, speed, and versatility makes it a cornerstone of modern fabrication. This article delves into the mechanics of Laser Cutting, its defining characteristics supported by technical data, its diverse applications, and essential maintenance protocols to ensure long-term operational integrity.

The laser cutting process fundamentally involves the generation of a coherent beam of light, which is then focused onto a material's surface. The intense energy density at the focal point rapidly heats, melts, and/or vaporizes the material. A high-pressure stream of assist gas, such as Nitrogen or Oxygen, is concurrently used to eject the molten material from the kerf (the cut width), resulting in a clean, high-quality edge. The process is controlled by a computer numerical control (CNC) system, which directs the laser head or the workpiece along a pre-programmed path, enabling the creation of highly complex two-dimensional shapes with extreme precision.

Exceptional Precision and Minimal Kerf Width: Laser cutting is renowned for its fine detail and tight tolerances. The focused spot size of the laser can be extremely small, often ranging from 0.1 to 0.3 millimeters. This allows for a typical kerf width as narrow as 0.05 mm to 0.5 mm, depending on the material and laser type. This minimizes material waste and enables the production of intricate features that are impossible with conventional mechanical tools. Positional accuracy is typically within ±0.05 mm, and repeatability can be as high as ±0.02 mm.

Superior Cut Quality and Edge Finish: The non-contact nature of the process eliminates tool wear and mechanical distortion, producing edges with a very smooth surface finish. For many materials, especially metals, the resulting cut often requires no secondary finishing operations. The Heat-Affected Zone (HAZ), the area of material altered thermally but not melted, is typically very small, often less than 0.5 mm in metals, which preserves the material's structural properties near the cut edge.

High Processing Speed and Throughput: Laser cutting is significantly faster than many traditional cutting methods, especially for thin materials. For instance, a 4 kW fiber laser can cut 10 mm thick mild steel at speeds exceeding 2.5 meters per minute, while a 1 mm thick stainless steel sheet can be cut at speeds over 25 meters per minute. This high throughput is critical for mass production and just-in-time manufacturing environments.

Versatility in Material and Application: A key advantage of laser cutting is its ability to process a vast array of materials, including a wide range of metals (steel, aluminum, titanium, brass), plastics (acrylic, polycarbonate, ABS), wood, composites, glass, and ceramics. Different laser types (CO2, Fiber, Nd:YAG) are optimized for different material groups, with fiber lasers demonstrating exceptional efficiency in cutting reflective metals.

Non-Contact and Automation-Ready: Since the laser beam does not physically touch the material, there is no tool force, eliminating the risk of contamination or mechanical damage to the workpiece. This characteristic, combined with CNC control, makes laser cutting systems ideal for full automation. They can be seamlessly integrated into robotic loading/unloading systems and flexible manufacturing cells (FMCs), enabling 24/7 unattended operation.

Automotive and Aerospace: Used for cutting high-strength steel chassis components, aluminum body panels, titanium engine parts, and intricate interior components. The precision and ability to cut lightweight materials are crucial for these industries.

Electronics and Semiconductors: Employed for creating precise enclosures, flexible circuit boards (FPC), and semiconductor wafers. The ultra-fine kerf allows for the miniaturization of components.

Medical Device Manufacturing: Essential for producing highly complex and sterile devices such as stents, surgical instruments, and implants from materials like stainless steel and titanium, where absolute precision and clean edges are non-negotiable.

Architecture and Construction: Used for fabricating structural steel components, decorative metal panels, and intricate artistic installations. It allows for the creation of complex designs in metal, wood, and acrylic for both functional and aesthetic purposes.

Consumer Goods and Signage: Widely used for creating custom products, personalized items, and signage from acrylic, wood, and leather. It is the primary technology for Rapid Prototyping and small-batch production.

Proper and regular maintenance is paramount for sustaining the cutting quality, operational safety, and longevity of a laser cutting system. A comprehensive maintenance regimen includes daily, weekly, and periodic tasks.

Visual Inspection: Check the external lens and nozzle for any spatter, dust, or damage.

Cleaning the Lens and Nozzle: Gently clean the focusing lens and the cutting nozzle using high-purity, lint-free swabs and a suitable optical cleaner like isopropyl alcohol. A dirty lens can scatter the laser beam, reducing power and cut quality.

Check Assist Gas Pressure: Ensure the gas pressure and purity are at the recommended levels for the materials being processed.

Inspect the Chiller: Verify that the laser source and optics chiller is functioning correctly, maintaining the required temperature to prevent thermal overload.

Clean the Exhaust System: Check and clean or replace the filters in the fume extraction system to maintain efficient smoke and particulate removal. A clogged filter can lead to poor cut quality and contamination of the optics.

Inspect and Clean the Beam Path: Check for dust or contamination on mirrors and other optical components within the beam delivery system. Clean them carefully using the prescribed method.

Check Mechanical Components: Inspect guide rails, ball screws, and drive belts for wear, and ensure they are properly lubricated according to the manufacturer's specifications.

Laser Power Calibration: Use a calibrated power meter to verify the actual output power of the laser source against its set value. A drop in power indicates potential issues with the laser resonator.

Beam Alignment: Perform a full beam path alignment to ensure the laser beam is centered through the nozzle. Misalignment can cause inconsistent cuts, taper, and reduced edge quality.

Professional Servicing: Schedule a comprehensive inspection and service by a qualified technician from the equipment manufacturer. This may involve checking the health of the laser source itself, replacing consumables, and updating system software.

Adherence to a structured maintenance schedule not only prevents unplanned downtime but also ensures that the system consistently operates at its peak performance, delivering high-quality results and protecting the significant capital investment it represents.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2026 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang