Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2025-12-04 11:08:30

In today’s industrial landscape, sheet metal components play a vital role in almost every sector — from consumer electronics and household appliances to automotive parts, medical devices, and industrial equipment. Behind these precision-made metal parts stands a key professional: the sheet metal fabricator. But what exactly is a sheet metal fabricator, and why are they essential in modern Sheet Metal Fabrication and metal fabrication industries?

A sheet metal fabricator is a trained specialist who transforms flat metal sheets—such as stainless steel, aluminum, copper, carbon steel, or galvanized steel—into finished components or assemblies. They use a blend of technical skills, engineering knowledge, and advanced machinery to cut, bend, weld, stamp, fold, punch, and assemble metal into functional products.

Sheet metal fabricators often work in specialized factories that offer complete sheet metal fabrication services, which may include:

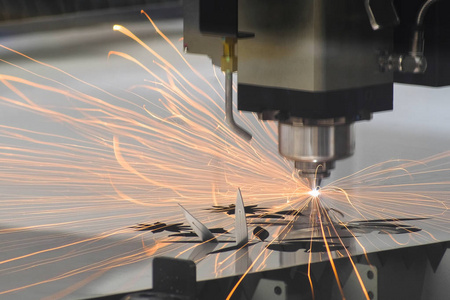

Laser cutting

CNC bending

Metal stamping

Welding and polishing

Surface finishing (powder coating, anodizing, plating)

Assembly and packaging

Modern fabricators operate in a highly automated environment where CNC equipment, robotics, and digital measurement tools ensure consistent quality and efficiency.

A sheet metal fabricator handles the entire production process—from raw material to finished product. Their work covers several critical stages:

Fabricators read engineering drawings, 3D models, and product specifications to understand dimensions, tolerances, and materials.

They use computerized laser machines to cut metal sheets with high accuracy, which is essential for industries requiring precision.

Fabricators operate press brakes or panel bending machines to achieve perfect angles and shapes. This stage represents the core of sheet metal fabrication.

TIG welding, MIG welding, spot welding, and riveting are widely used to assemble metal components into final structures.

To improve appearance, corrosion resistance, and durability, fabricators provide finishing options such as painting, powder coating, anodizing, or polishing.

Using measurement tools, testers verify tolerances, structural integrity, and finish quality before shipment.

The demand for customized metal components has pushed fabrication factories to become More flexible, precise, and efficient. Sheet metal fabricators provide significant value in several ways:

Metal sheets offer excellent strength-to-weight ratios, making them ideal for automotive, aerospace, and electronics.

Tools and automation reduce labor and production costs.

Fabricators support custom parts, OEM/ODM projects, and flexible production volumes.

Modern fabrication shops integrate rapid CNC Machining, cnc prototype service, and prototype manufacturing to create complex components more efficiently.

The sheet metal fabrication process combines traditional craftsmanship with advanced digital machining. Below is a typical workflow:

Design and Engineering

2D or 3D drawings are created for production.

Material Selection

Fabricators choose metals based on strength, corrosion resistance, and application needs.

Laser Cutting / CNC Punching

High-speed machines cut or pierce the sheet.

Bending / Forming

Press brakes shape the metal into required angles.

Welding and Assembly

Parts are joined to form solid structures.

Finishing and Coating

Surface treatments enhance performance and appearance.

Final Inspection

Ensures tolerances and quality standards are met.

Although the terms are sometimes used interchangeably, there is a difference:

| Category | Sheet Metal Fabrication | Metal Fabrication |

|---|---|---|

| Materials | Primarily thin metal sheets | Includes sheet metal, heavy steel, tubing, cast metal, etc. |

| Uses | Enclosures, brackets, housings, cabinets | Structural beams, frames, pipes, machinery |

| Equipment | Laser cutter, press brake, CNC bender | Welding stations, cutting torches, heavy-duty mills |

Sheet metal fabrication is considered a specialized branch of metal fabrication, focused on producing precision thin-wall parts.

For global product developers and OEM manufacturers, one major advantage of modern sheet metal fabricators is their ability to support both rapid prototyping and mass production.

Fabricators often integrate CNC Machining centers to help create prototype parts before mass production. This helps verify:

Design accuracy

Assembly fit

Functional performance

Fabricators can produce small batches with short turnaround times, ideal for new product testing.

With advanced milling and turning systems, complex details or non-standard parts can be quickly machined and integrated with sheet metal components.

This comprehensive capability allows factories to function as full-process manufacturing service providers instead of single-process suppliers.

Choosing an experienced sheet metal fabricator provides multiple advantages:

CNC-controlled equipment ensures tolerance consistency for demanding industries like electronics or medical devices.

Fabricators process stainless steel, aluminum, copper, carbon steel, brass, etc.

Automated cutting and bending systems shorten production cycles.

Efficient material utilization reduces waste and lowers overall costs.

From design to assembly, professional factories offer complete fabrication services to global buyers.

Sheet metal is used in almost every industry, including:

Electrical cabinets and enclosures

Machinery housings

Automotive brackets and components

Aerospace parts

Medical equipment covers

Consumer electronics casings

HVAC systems

Industrial frames and platforms

Lighting fixtures

Custom hardware components

The versatility of sheet metal makes it indispensable in the modern manufacturing world.

A sheet metal fabricator is far more than a machine operator — they are skilled professionals combining engineering knowledge, craftsmanship, and advanced CNC technology to produce high-quality metal components. Whether you need sheet metal fabrication, metal fabrication, cnc prototype service, prototype manufacturing, or rapid cnc machining, working with a reliable fabricator ensures precision, efficiency, and competitive cost advantages.

For global buyers seeking dependable manufacturing service partners, understanding the role and capabilities of a sheet metal fabricator is the first step toward building strong, long-term industrial cooperation.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2026 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang